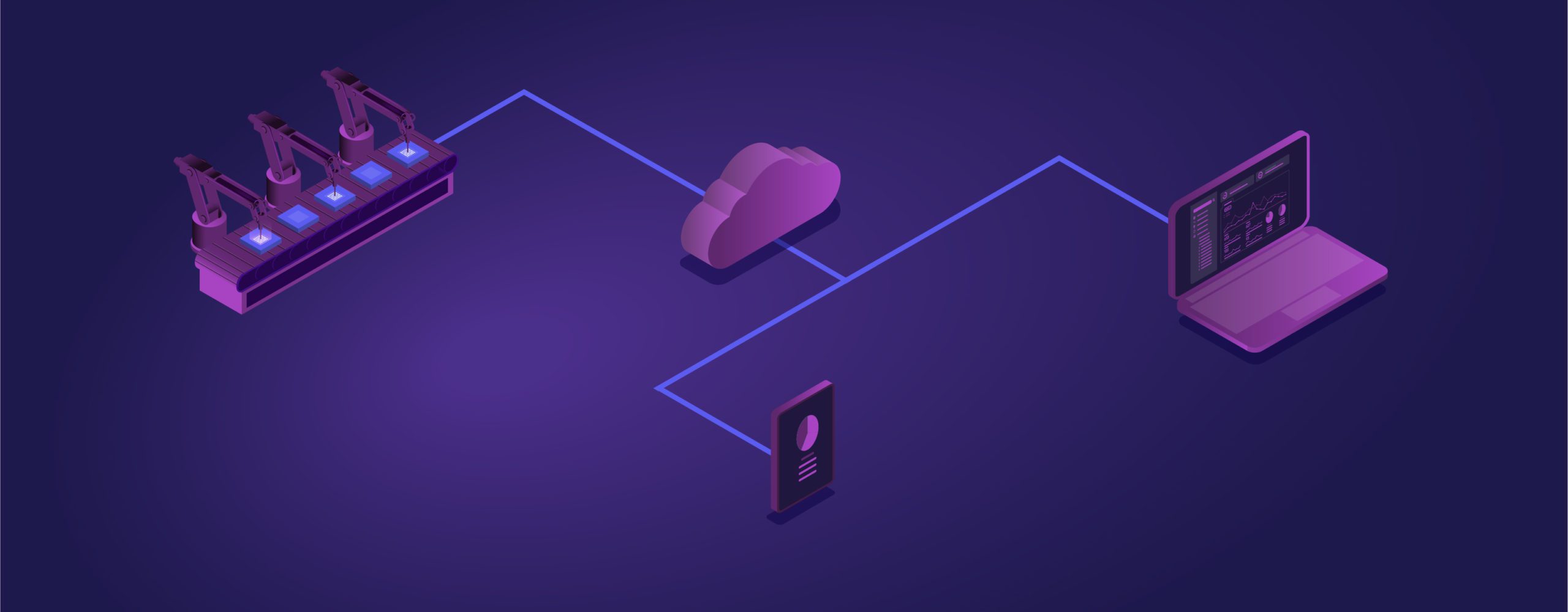

Connected Factory

A connected factory is a factory that links manufacturing devices to the cloud and provides intelligence on all aspects of the production process. This can take place over several production sites. In an industry 4.0 context, a connected factory doesn’t just rely on IoT for data collection but wants to provide an intelligent link to business processes.

Often, industrial installations already generate data but are coping with heavy legacy software. Because the cost of components for connectivity substantially decreased during the last few years, connected factories are emerging everywhere.

Use cases

Monitor & control installations on several locations

Get more data on operations

Detect anomalies and receive alerts

Optimize maintenance cycles

Speed up testing of new equipment

Build better workflows and improve quality

Automize inventory flows

Reduce energy consumption

Waste reduction

For whom?

Why connected factory might be right for you.

The ‘Connected Factory’ concept is especially relevant for production companies that want to speed up innovation on the manufacturing floor and need technology support to realize their ambitions.

Benefits

Benefits of public cloud

Stable and secure infrastructure

Stable and secure infrastructure

Storage of production data

Storage of production data

Scalable environment

Scalable environment

Engineering solutions

Engineering solutions

How can we work together?

Our team of experts is eager to help you build the best cloud strategy possible.

1.

Project intake

Let us help determine your business objectives and current processes.

2.

Analyze

We analyze the current technologies in use.

3.

Roadmap

We build a roadmap and a budget framework for you. 4.

Kick-off

We kick off the implementation.

5.

Support

We provide ongoing support.